Back to Services

Health & Saftey

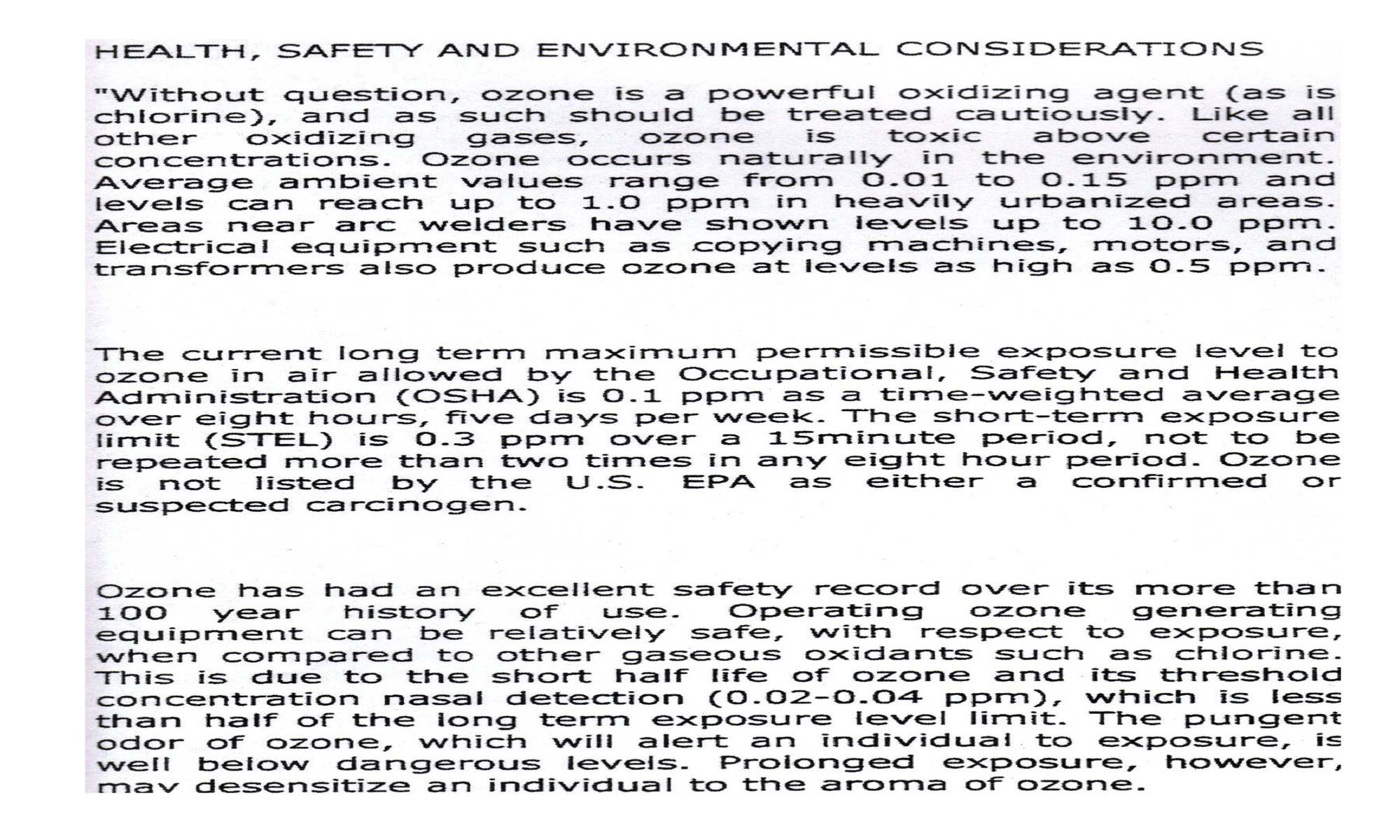

Health and Safety. Environmental considerations. Without Question, Ozone is a powerful oxidizing agent (as is chlorine), and as such should be treated cautiously. Like all other oxidizing gases, ozone is toxic above certain concentrations.

Click here to download and View this Power Point of the Safety Requirements.

Levi's Ozone Safety Requirements. Update of SES Guidebook

Below is the Levi Strauss & Co Ozone Safety Requirements that applies to all factories.

Ozone Application

This information applies to all factories covered by the Social and EnvironmentalSustainability (SES) program for Levi Strauss & Co.

Background

Some factories use ozone as a bleaching agent in the fabric or garment finishing process.Ozone generators use an electrical current to charge oxygen molecules in the incoming air

and produce ozone. Ozone is an irritant gas and may cause health effects that range from

irritation of the eyes, nose, throat and chest to severe injury. Ozone is also a strong

oxidizing agent and may pose a fire or explosion hazard under certain circumstances.

Purpose

The purpose of this section is to explain the safety requirements for ozone generators andassociated equipment in order to prevent accidents, injuries and/or illnesses that could

result from exposure to ozone gas. The requirements set out below shall be followed for

each ozone finishing installation at each manufacturing facility in order to achieve the

LS&Co. required 3 level safety: 1, isolation 2, ventilation 3, detection.

SES Requirements

Ozone Generator Safety

1. IA Factory shall isolate ozone generators from the rest of the factory by enclosing them in their own room by using a physical cover (e.g. brick, glass or polycarbonate walls...etc.).2. IA The ozone Generator room shall have ozone-resistant exhaust ventilation linked to outside.

3. IA Factory shall equip areas in which ozone generators are located with an ozone monitor and an audible and visual alarm that will alert if ozone level exceeds 0.3 ppm.

4. IA The ozone generator shall have at least 2 shut off switches:

- On the generator

- Outside of the ozone enclosed area

5. IA Equipment associated with the ozone generator (such as pipes, pipe connectors, and clamps) shall be made of ozone-resistant materials and must be strong enough to withstand the pressure generated by the ozone finish process.

6. IA Connection pipes between generator room and ozone treatment equipment shall be enclosed through use of a rigid tube/channel for physical protection.

7. IA All sensors in the system shall be kept switched on at all times when the ozone generator is in operation (e.g., if generator is supplying only one washer out of several, – sensors should not be turned off on any machine).

Ozone Finishing Equipment Safety

8. IA Factory shall isolate ozone equipment (except vacuum type machine) from the rest of the factory by enclosing it in a seperate room by using a physical cover (e.g. brick, glass or polycarbonate walls...etc.).

9. IA Factory shall isolate integrated ozone equipment (when washer and generator built in one piece) from the rest of the factory by enclosing it in a separate room by using a physical cover (e.g. brick, glass or polycarbonate walls...etc.).

10. IA The ozone Finishing Machine room shall have ozone resistant exhaust

ventilation linked to outside in order to suck air away from the work area. The

ventilation can stop only if the whole installation is switched off (all generators and washers).

11 . IA N egative pressure ozone finishing

machine shall be equipped with an exhaust ventilation in order to maintain constant negative pressure inside the machine. The ventilation can stop only if the whole insta llation is switched off (all generators and washers).

12 . IA The control panel of the ozone machine shall be visible from outside the ozone machine room (or be"installed outside) and factory shall

make sure that operator is not staying inside the room during the ozone treatment process.

13 . IA Excess or exhaust ozone shall be ventilated through an ozone-destruct unit. The ozone-destruct unit may use either thermal/steam or catalytic conversion technology and must destroy ozone.

14 . IA Final discharge after destructor shall go through a vertical chimney high enough to avoid human exposure.

15 . IA F inal discharge after destructor to the environment shall be monitored in order to identify when destructor needs to be maintained and to verify that the unit is capa ble of destroying the amount of ozone moving through it.

16 . IA Ozone concentration inside the ozone chamber shall be monitored to ensure the machine is locked until the ozone is at or below 0.2 ppm.

17 . IA F actory shall also install an ozone monitor and audible a nd visual alarm close to the washer door to alert for immediate evacuation from that area if ozone levels exceed 0.3 ppm.

18 . IA Pipes, connectors, sealants and clamps shall be made of ozone-resistant materials (e.g., stainless steel connectors for tubing). N ote: this is applicable for all parts.

19 . IA Second door and dosing system on washer shall have automatic lock so it cannot be opened.

20 . IA F actory sha ll evaluate ozone exposures to workers on regular basis by performing an official work environmental survey.

21 . IA F lammable or combustible materials shall not be stored in the same room as the ozone g enerator.

22 . IA Factory shall have at least one Self- Contained Breathing Apparatus (SCBA) available for emergency use.

23 . IA Factory shall have an air-purifying, full-facepiece respirator (gas mask) with a chin-style, front or back mounted canister providing protection against ozone. Only monoxidizable sorbents are allowed (not charcoal).

24 . CI Employees shall be trained annually on the hazards of ozone gas and on the need to stay out of (or evacuate) the ozone installation area if the alarm has been triggered.2 5 . CI Factory shall have written standard operating and maintena nce procedures for safely operating the ozone installation in local language.

26 . CI Machine shall be labelled in a language understood by operators and maintenance personnel.

27 . IA The safety features of the machine, including the computer program, shal be protected and modified only with

the agreement of the ozone machine manufacturer and the concurrence of LS&CO.

SCBA for emergency or planned entry into

unknown concentrations or IDLH (Immediately

Dangerous to Life or Health) conditions.

28 . IA In case any safety button is pushed

the generator shall be stopped and destruction process shall start up at each washer.

29 . CI All ozone- related documetation must be available to Assessors for review.

Implementation of SES Requirements

Training, Rules, and Record Keeping Factory shall train operators and maintenance staff annually regarding the hazards of ozone gas and regarding the equipment use and safety controls in place.

Factory shall keep written records to show ozone safety training has been completed.

Hazard Controls

• Factory shall periodically calibrate and maintain the ozone-monitoring equipment to make sure that it works properly and provides accurate information about ozone levels. Factory shall follow ozone sensor manufacturer’s written instructions.

• Factory shall periodically test and maintain the ozone alarms to ensure they are working properly.

• The safety visual and audible alarm signal must be easily distinguis hed from process alarms.

• Factory s hall periodically maintain self- contained breathing apparatus (S CBA).

Factory shall follow SCBA manufacturer’s instruction.

Full-facepiece respirator (gas mask) with a chin-style front or back mounted canister for escape

Full-facepiece respirator (gas mask) with a chin-style front or back mounted canister for escape

Save Money, Save Time

Save Money, Save Time